-

Schedule a Tour

Want a tour of our facility?

Click Here to fill out a Request Form and one of our staff will contact you to schedule your visit.

-

Certifications

Spectral Response is proud to have earned recognition with these certifications:

- ISO 9001

- ISO 13485

- AS9100C

- IPC-610 Certified Trainers and Operators

- IPC-620

- J-STD Certified Trainers and Operators (with Space Addendum)

- ITAR Registered & Compliant

- 100% Security Verifications Employee & Visitor

- RABQSA Certified AS9100 Lead Assessor Certification

- ESD System ANSI/ESD S20.20 compliant

Engineering

Our diverse engineering team offers an extremely high level of expertise in the key electronic manufacturing, testing and engineering disciplines. We are able to support all your engineering needs from initial product concept all the way to production.

|

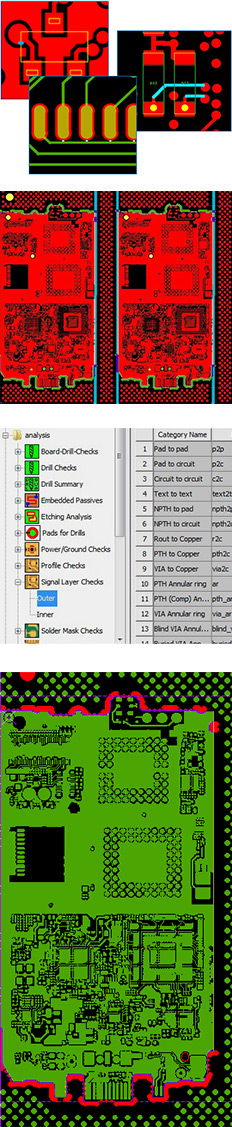

Valor™ Is A Key ToolValor is an end-to-end DFM/DFT solution for PCBA manufacturing, encompassing all phases from NPI [New Product Introduction] to assembly and test.

NPI

Test Development and Services

Engineering Production Services

|